Festool cordless Hammer and Percussion drills. Tips for choosing and using the right tool.

Screwdriving, drilling, percussion drilling and hammer drilling:

The new Festool cordless Quadrive TPC 18/4 percussion drill and the BHC 18 cordless hammer drill are powerful, versatile and, of course built to last!

Providing huge amounts of torque, speed and impact energy just like corded tools, but! These are not the only factors for a great drilling experience!

Important considerations are:

How do hammer mechanisms work?

Which drilling function is suitable for which construction material?

What is the material you are drilling into?

TPC 18/4

BHC 18V

Tradies know that ease of use is a non-negotiable when on the job.

Professionals know that when functions and attachments can be changed quickly, they are saving time, money and, doing a quality job!

This is why Festool has united the CENTROTEC tool chuck and bit holder into one unit: It's half the size and 80% lighter than comparable chucks.

It fits all Festool cordless drills and cordless percussion drills with the FastFix interface, enabling users to change tools in a matter of seconds. Minimal time wasted!

The CENTROTEC chuck

Hammer V Percussion. What's the difference?

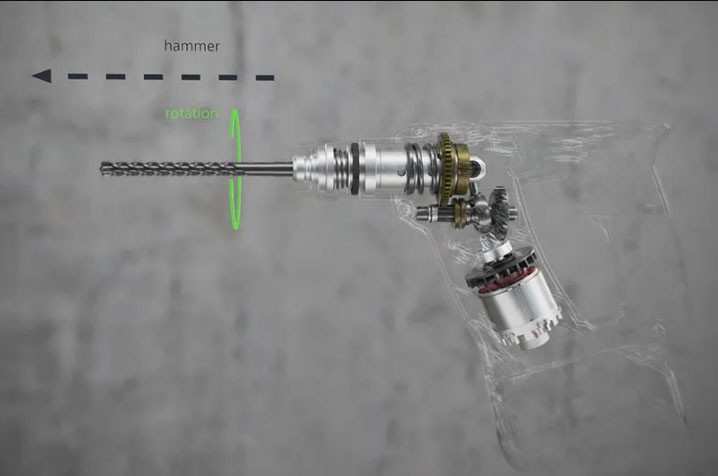

Use and function of the hammer drill

The BHC 18 hammer drill has a pneumatic hammer mechanism, which generates powerful impact energy that works in the axial direction.

The resultant rotational movement guides the drilling dust backwards.

A hammer drill works at a lower stroke rate, but with significantly greater impact energy than a percussion drill, this enables work to be completed faster.

Hammer drilling in concrete requires less force than percussion drilling.

Festool trainers recommend the BHC 18 hammer drill for harder construction materials such as concrete.

The BHC hammer action

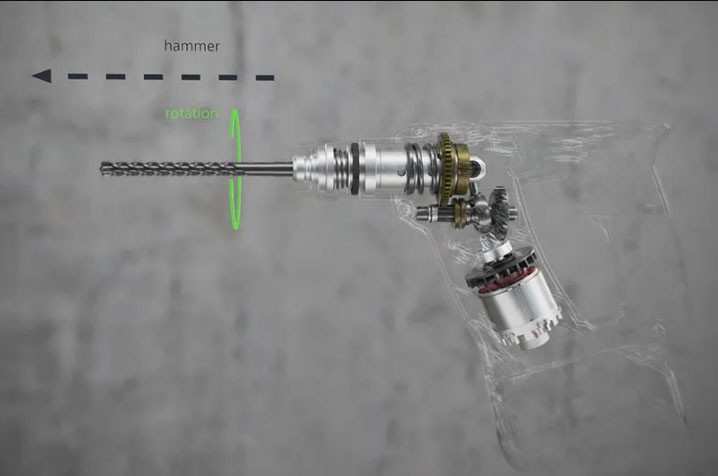

Use and function of a percussion drill

The hammer action works in the axial direction for percussion drills, too. Here, however, the function is generated by two tooth and notch discs, which come into contact with each other and "slide" on each other.

This process transfers hammer actions to the tool chucks, which act on the material via the drill bit.

During percussion drilling, many small hammer actions act in the axial direction of the drill bit. Thanks to the notch discs, a higher stroke rate is generated than with a hammer drill, but the impact energy is lower.

To optimise drilling progress, the user can press the cordless percussion drill tightly against the drilling point. For softer materials/panel materials, Festool recommends working without using hammer action – such as with fibre-cement panels, plasterboard, gypsum fibreboard, stone with porous joints (aerated concrete, pumice concrete), and masonry made of perforated brick.

The TPC percussion action

Other useful tips

Tips for identifying construction materials

Sometimes, construction materials are not easy to identify. As soon as the wall is plastered or covered, the exact construction material makes identification harder.

Carrying out a test drill with a small drilling diameter is the way to remedy this situation, making it easy to determine whatever is hidden under the surface, some tips below:

- Concrete: Very fine, white to grey drilling dust

- Solid brick: Red (usually, but can be other colours) drilling dust

- Cellular concrete: Light grey, coarse-grained drilling dust

- Perforated brick: Hollow spaces can be felt when drilling, light red drilling dust

- Plasterboard: Hollow space behind the boards, fine white drilling dust

- Sand-lime brick: Fine-grained, sandy white drilling dust

Cleaning the drilled hole

Cleaning the drilled hole is something that many people often underestimate: It is an important factor when installing mounting elements as drilling dust/debris in the drilled hole can reduce retention forces by more than 50 percent.

This is why Festool tool technicians recommend cleaning the drilled hole before installing plugs, anchor bolts or any other mounting elements.

When drilling, the rotational movement of the drill bit guides drilling dust backward, but fitting a drilling dust nozzle considerably reduces exposure to dust for users.

The D 27-BSD drilling dust nozzle is a practical, clean and most importantly, safe addition to your drilling arsenal.

With its patented two-chamber system, it ensures dust-free drilling with drill bits up to 12 mm in diameter on floors, walls and ceilings. This keeps the drilled hole clean, the job-site clean and dowels, plugs and anchors benefit from the better grip of a clean hole.

Safe working with the KickbackStop, ear protection and safety glasses

Working safely with tools is a Festool priority. This is why Festool put a huge effort into equipping its tools with unique and effective safety features.

Using the TPC cordless percussion drill and the BHC cordless hammer drill, the electronic KickbackStop reduces the risk of the drill suddenly jamming in the material, this minimises the risk of twisting your wrist and causing severe injury.

Despite the inbuilt safety features of our drills, when drilling, always wear effective ear protection and safety glasses.

Safety first!